Authorized Distributors of

Perfect chain sprocket interaction is critical for smooth and trouble free operation of Power Transmission system. This is the most critical part in driving success to a Power transmission process.

We provide the best of the sprockets to go with the best chains for the drive system. The sprockets are designed and manufactured to meet high quality standards which will maximize the overall system efficiency. A perfect Diamond chain and sprocket articulation will give a longer service life for both chains as well as sprockets, thus ensuring cost reduction. This means

- Reduced down time

- Reduced maintenance costs

- Increased productivity

- Diamond Sprockets are specifically designed & manufactured to suit over chain’s stringent tolerance levels.

- Superior quality medium carbon & alloy steels are used for better strength and wear resistance properties.

- The teeth are generated through mobbing and milling process.

- The blanks for sprocket are produced through forging and machined using CNC machines.

- The Bore of the sprockets is finished to closer tolerances & smoother surface finish by boring Operation

- Key ways in paired sprockets are produced by milling operation in a single stroke for better accuracy and alignment

- Sprocket tooth profiles are made as per standard ISO 606/ANSI B29.1

- 100% of the sprockets are subjected to wrap test with the corresponding chain for checking the fitment between chain and sprocket.

- Wrap test ensures correctness of P.C.D and Root Diameter which are critical for fitment at site.

- Sprockets and Traction wheels, the working portion will be Induction Hardened to higher case depth for better wear resistance based on request.

- The tooth portion where the chain roller engages will be hardened to resist abrasion.

- This enhances the working life of the sprocket 1 traction wheel.

- In paired sprockets, the key way alignments are checked and the straightness of the teeth ensured during inspection.

- This facilitates easy assembly of sprockets into the shafts at site.

- Diamond Sprocket are available across wide pitch group & tooth count

- Sprockets Comply with British Standards and with pilot Bore with type B

- Pitch: 3/8” to 1½"

- Tooth: 9 to 76

- Strands: Simplex, Duplex & Triplex

Diamond sprockets are also available for specific applications based on request.

They have application engineers who can serve on customised requirements.

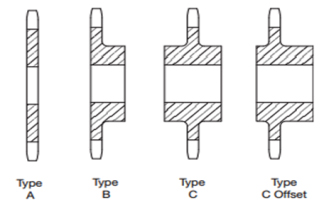

Although, Hub type B is the standard, other types of hub also available as listed below:

Customer need to select the appropriate Hub type requirement

See attached catalogue for the dimensions of various types of sprockets.